AbrasivesAdhesives & TapesAir Tools & CompressorsCutting ToolsMWF Coolant ControlHand ToolsIndexible Cutting ToolsIndustrial Oil & LubricantsPrecisions & MeasurementsRaw Materials & FastenersSafety & JanitorialStorage & CabinetsToolholding & Workholding

Abrasives

- Buffing Items

- Coated Abrasives

- Cut off Wheels

- Diamond Wheels

- Dressing Stones

- Flap Wheels

- Dressing Polishing Grinding Wheels

- Lapping

- Mounted Points

- Scotchbrite Products

- Sheets & Rolls of Abrasives

- Wire Wheels

- Flap Discs

Adhesives & Tapes

- Araldite

- Dunlop Fix o Fix

- Gasket Adhesive & Compounds

- Loctite Industrial Range

- Retaining Adhesive & Compound

- Thread Locking Adhesives

- Super Glues & various tapes

Air Tools & Compressors

- 5-150 CFM Air Compressors

- Air Tools

- Air Hose, Various Specs & Lengths

- Pneumatic Fittings & Couplings

- Spraying Guns &s

Cutting Tools

- Band Saw Blades

- Boring Tools

- Brazed Tools

- Burr’s

- Counterbores

- Countersinks

- Dies

- Drills

- Holesaws

- Knurls

- Milling Cutters

- Reamers

- Slitting Saws

- Side Face Saws

- Taps

- Toolbits

- Turning Tools

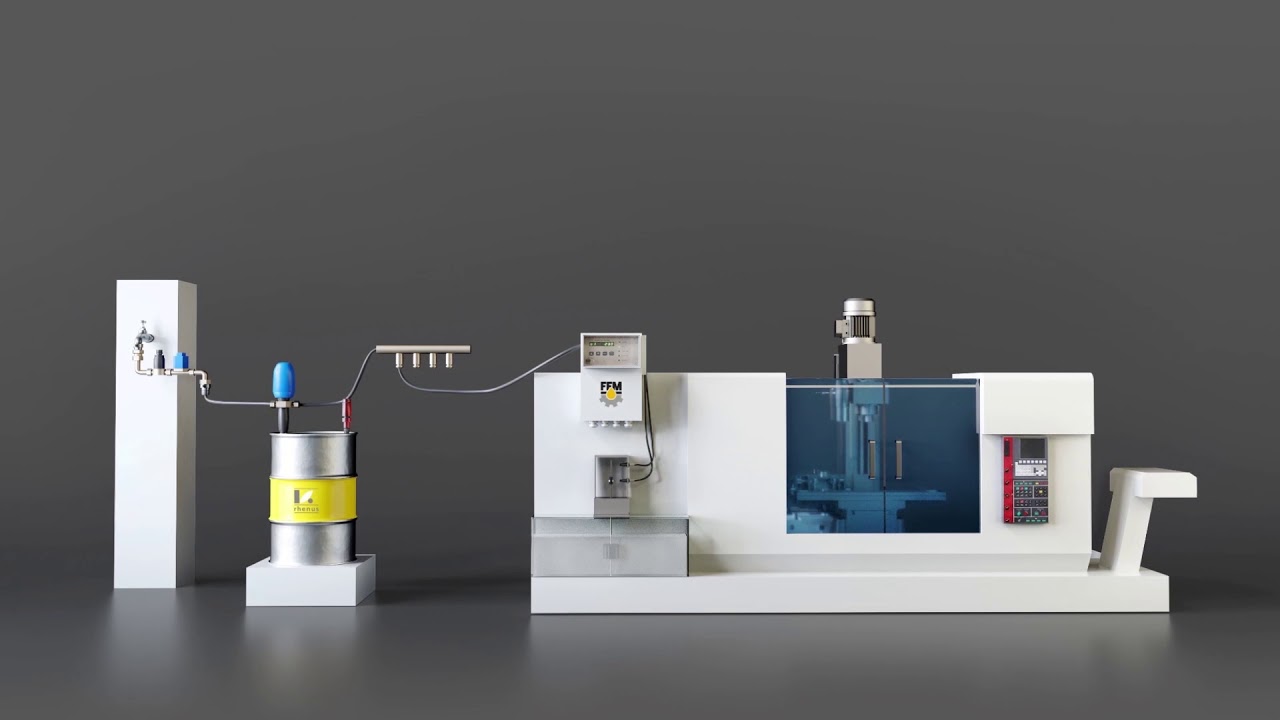

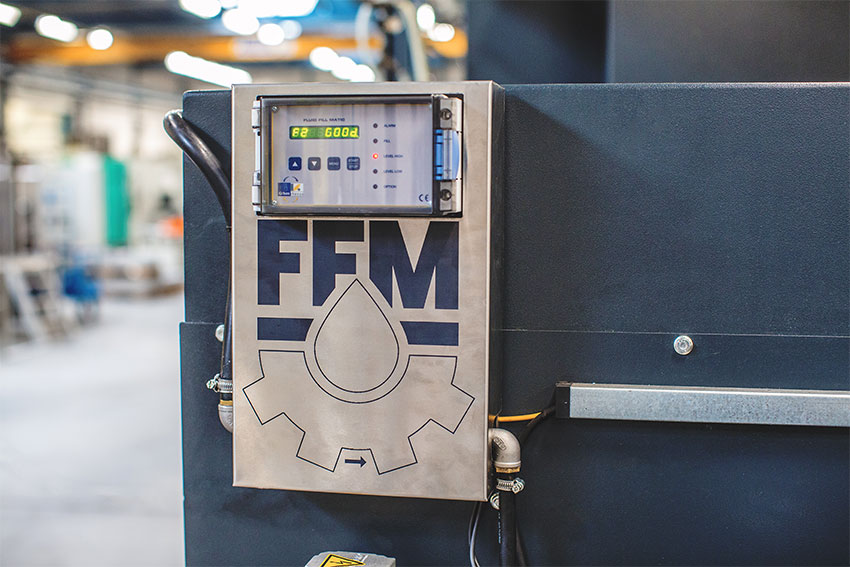

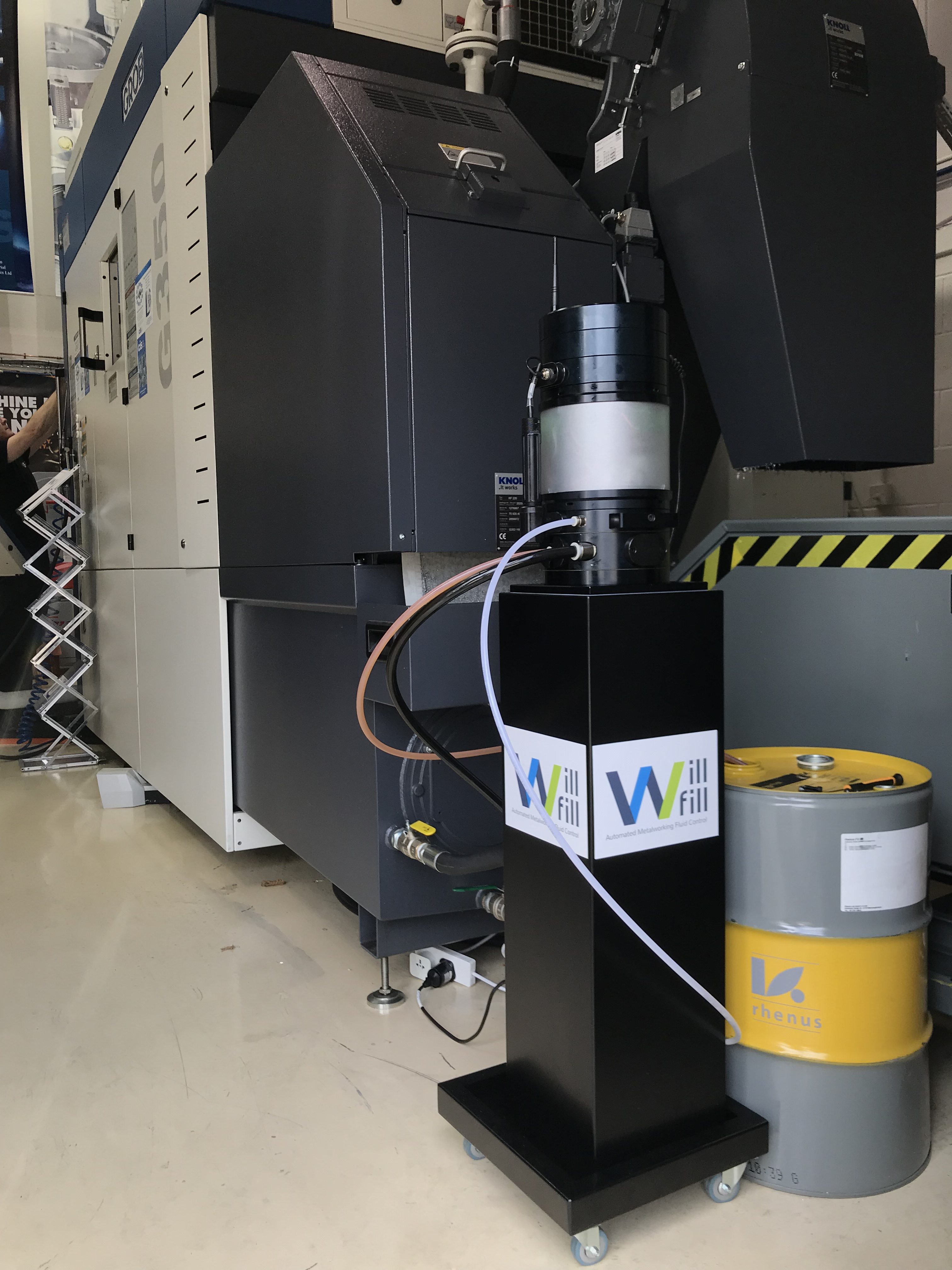

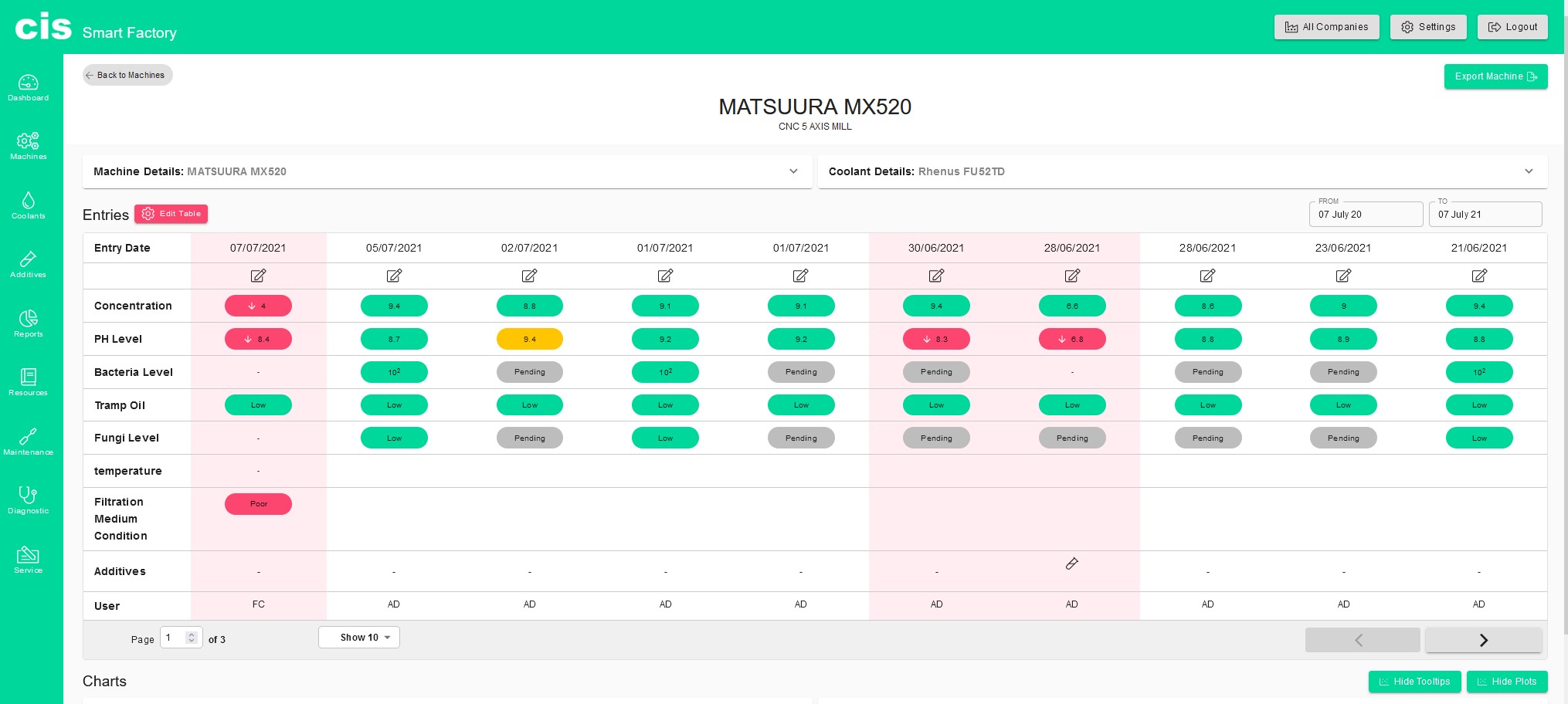

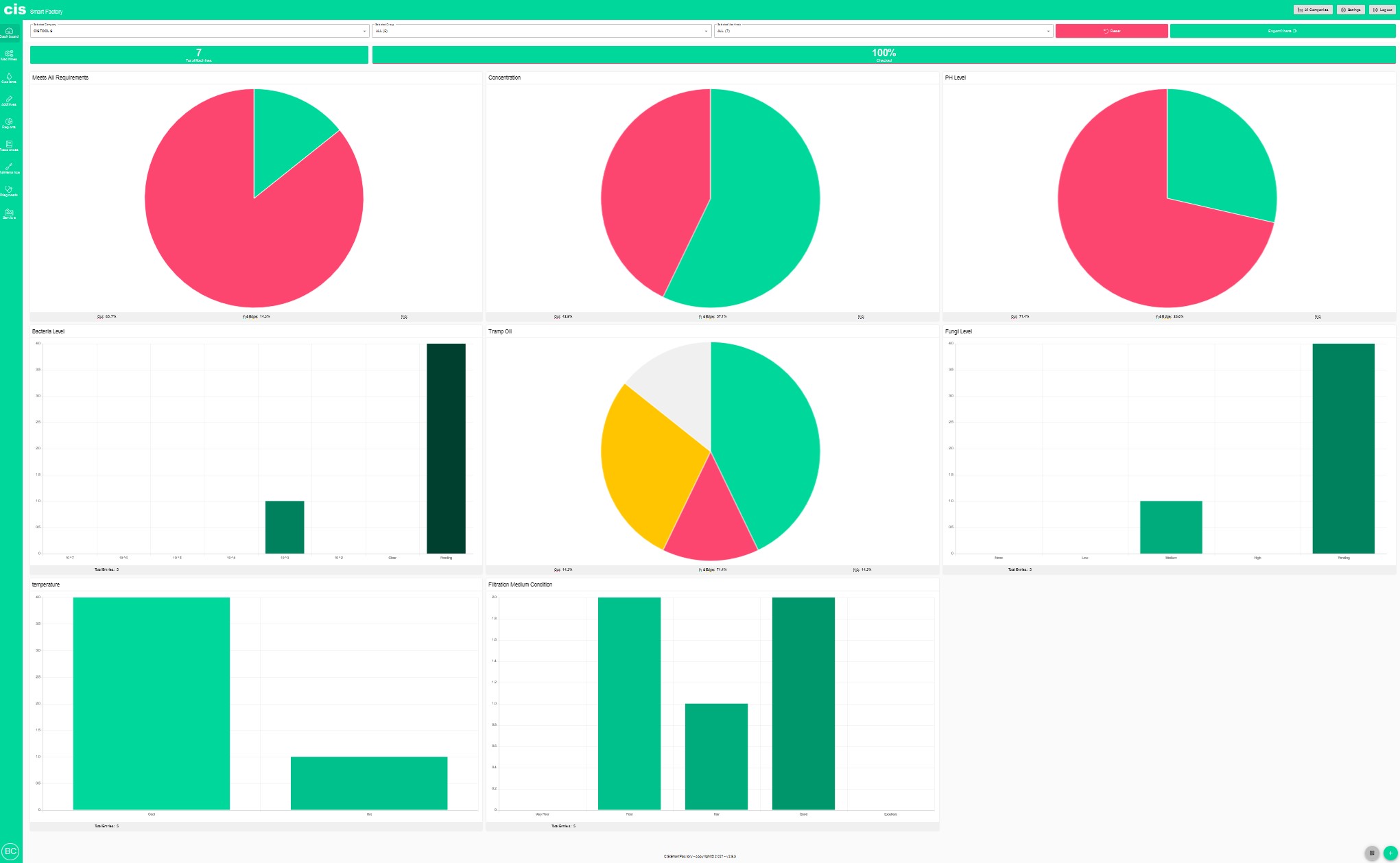

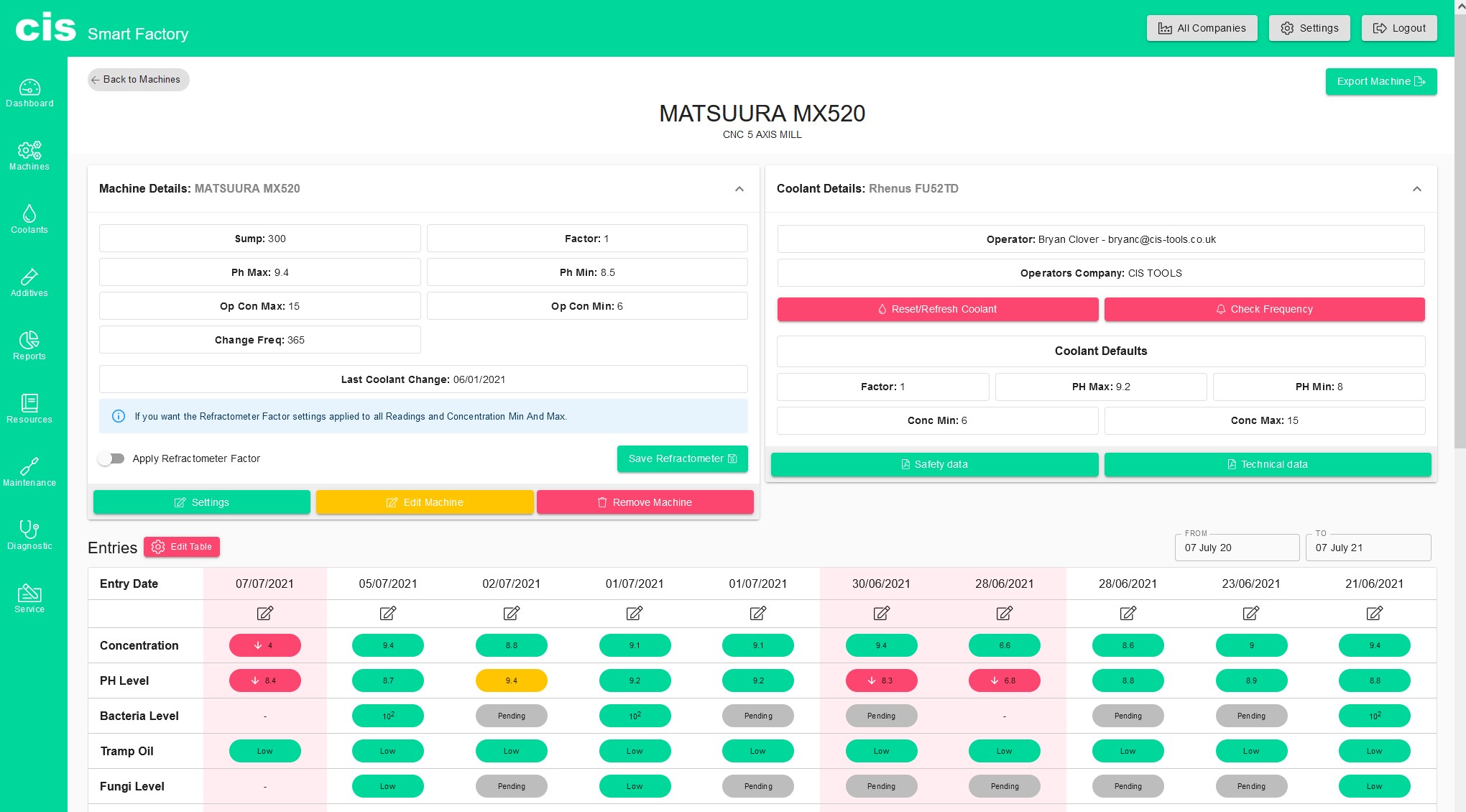

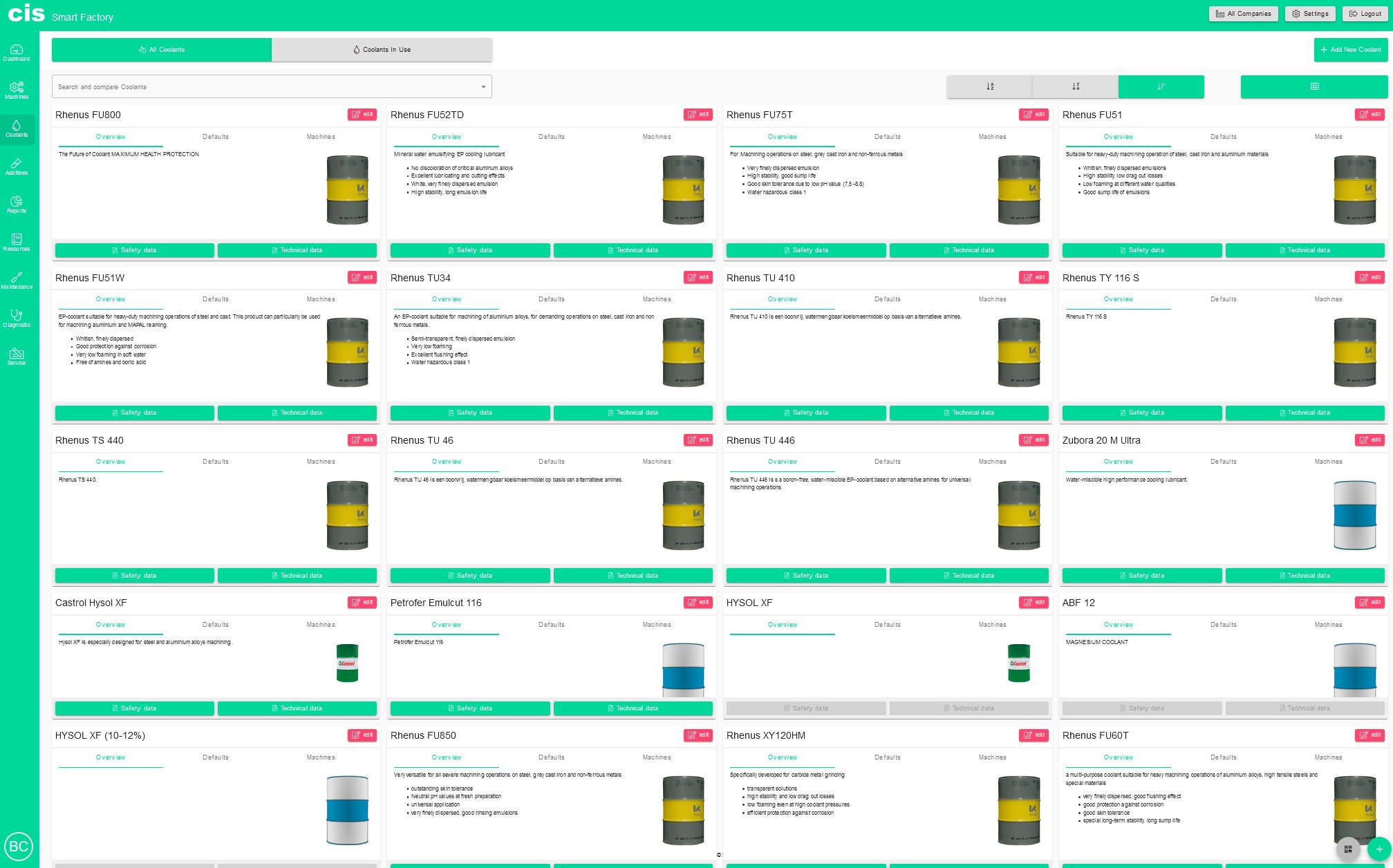

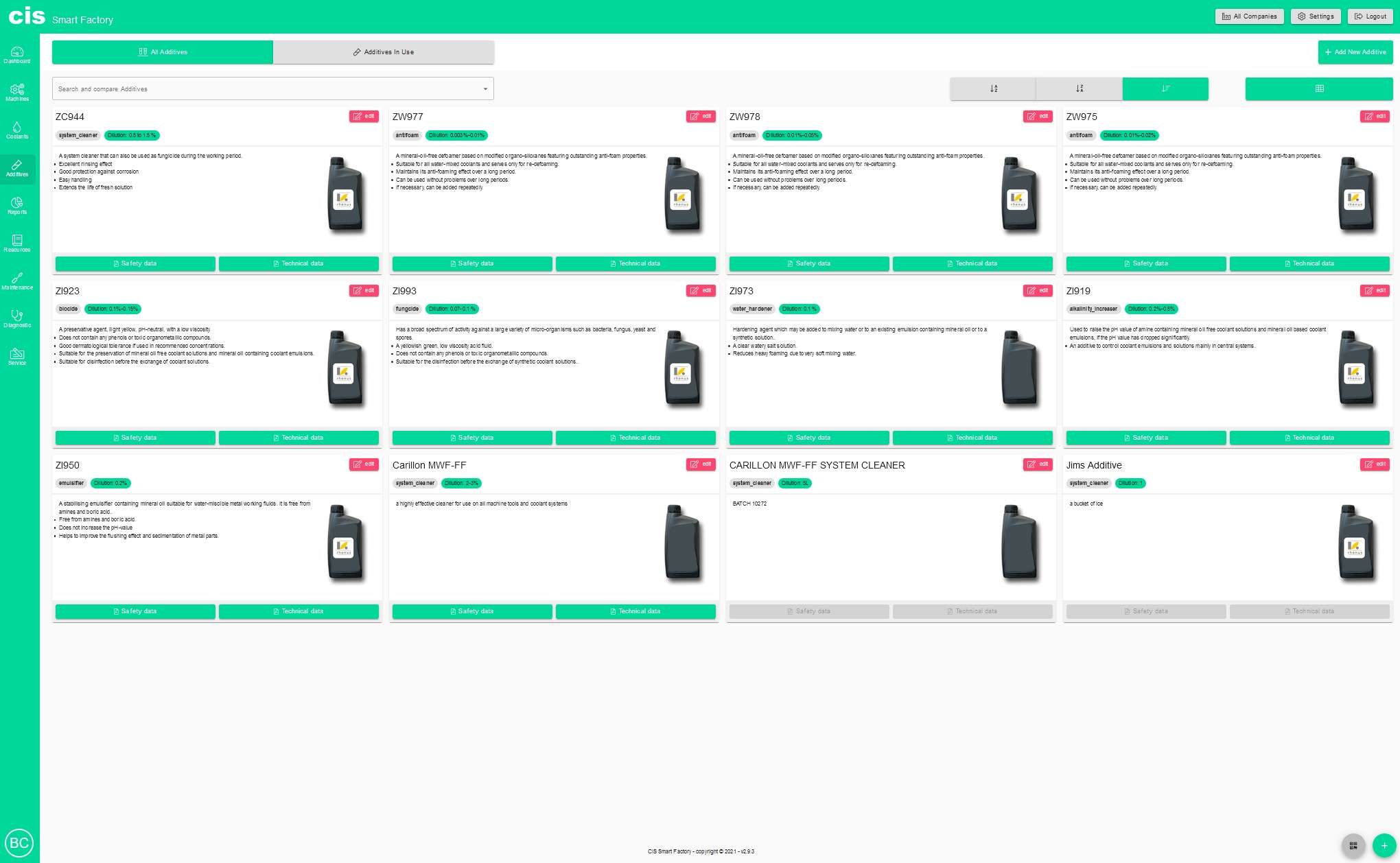

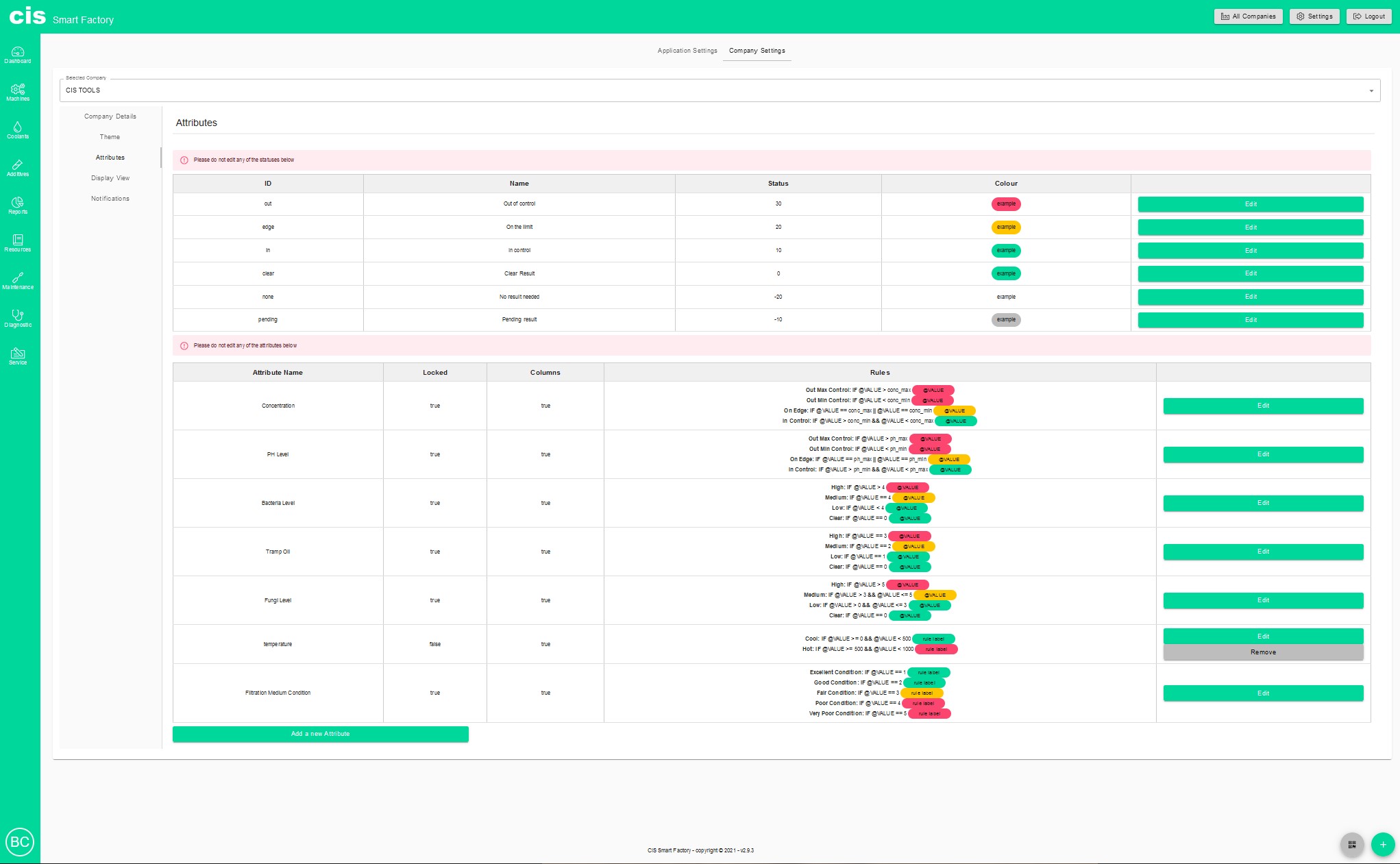

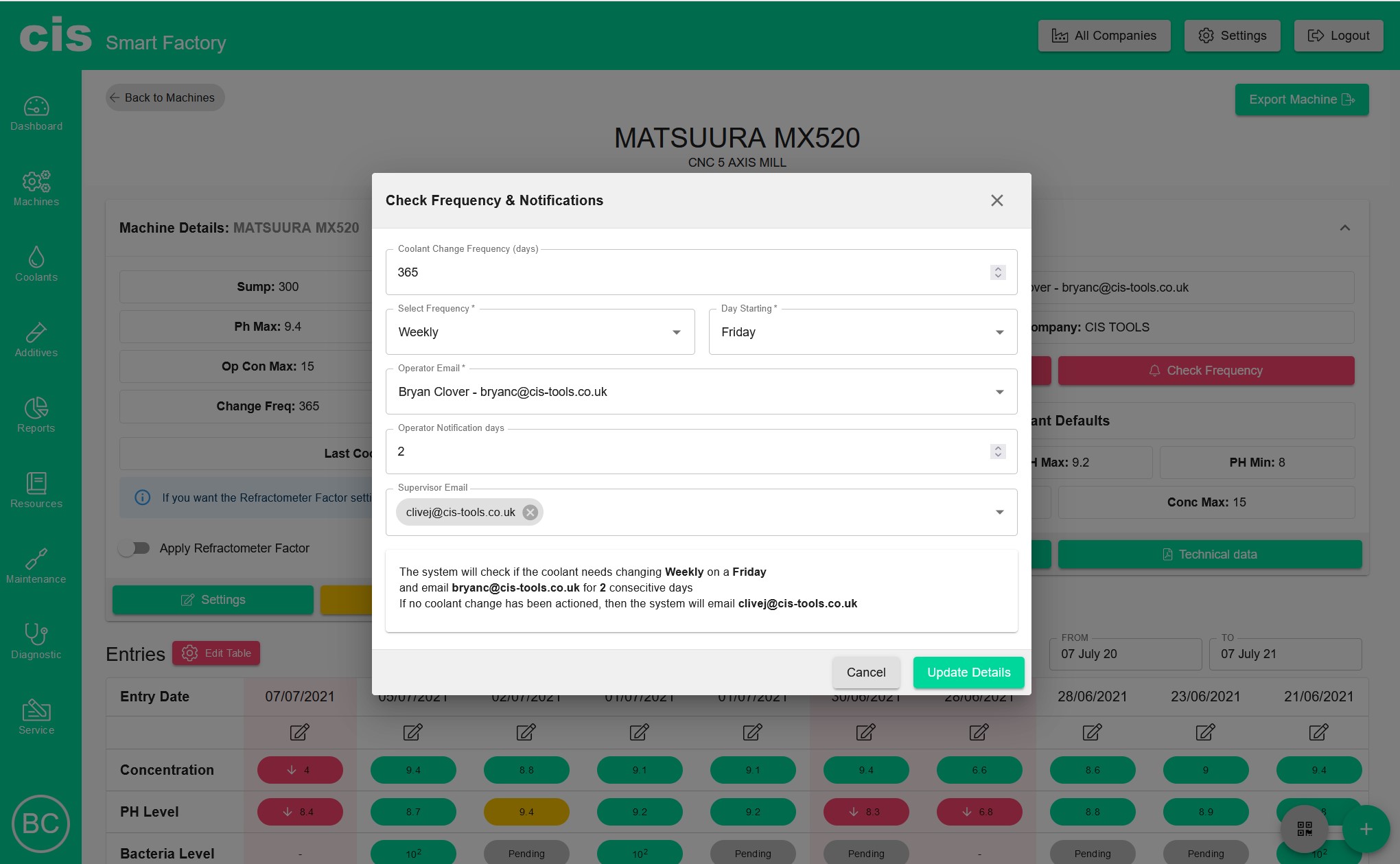

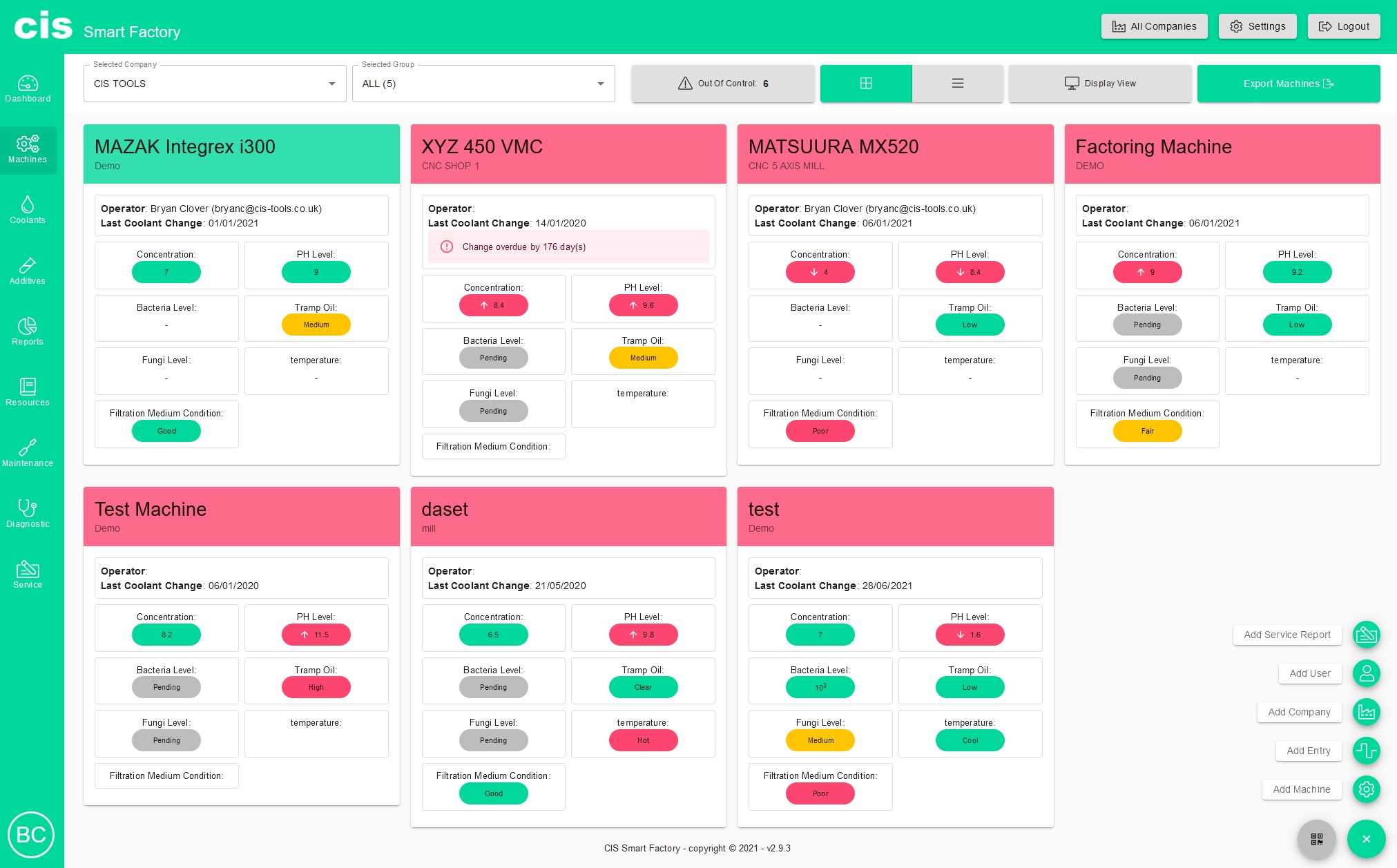

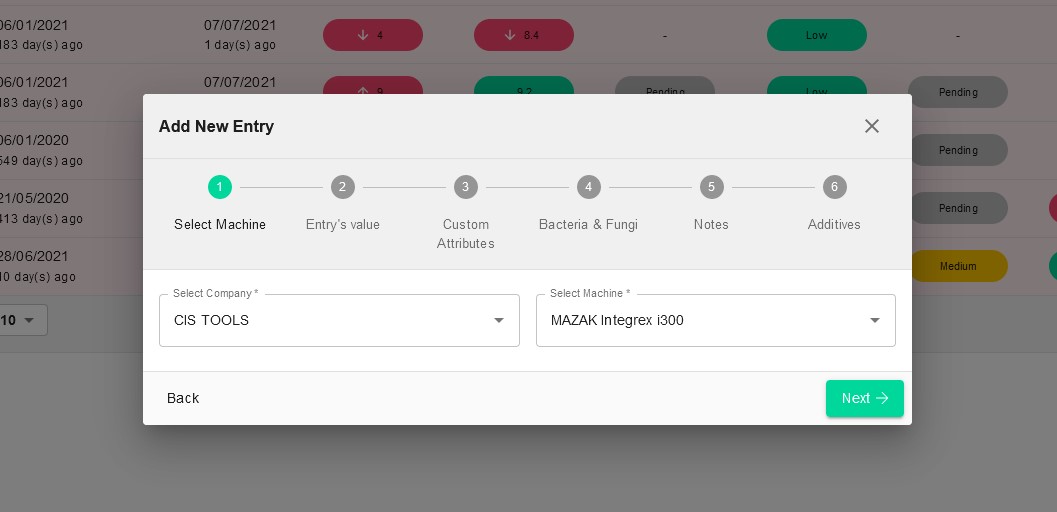

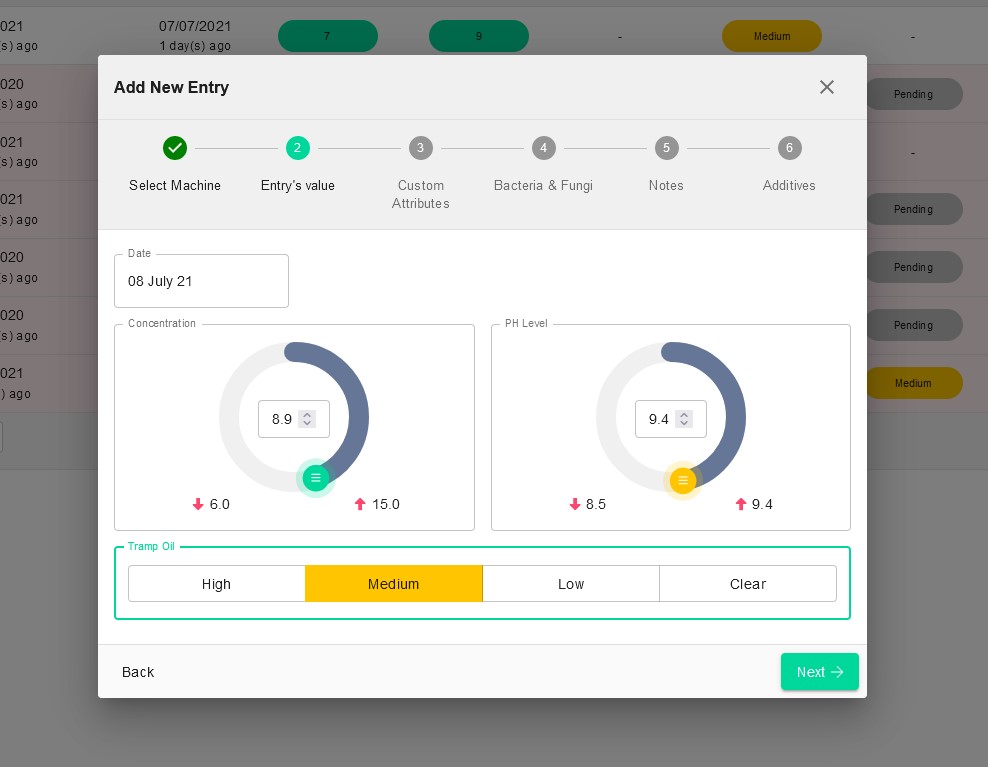

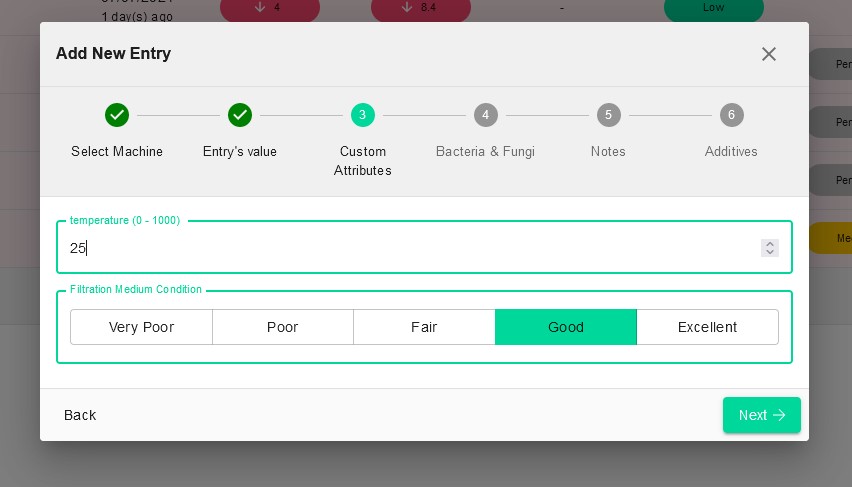

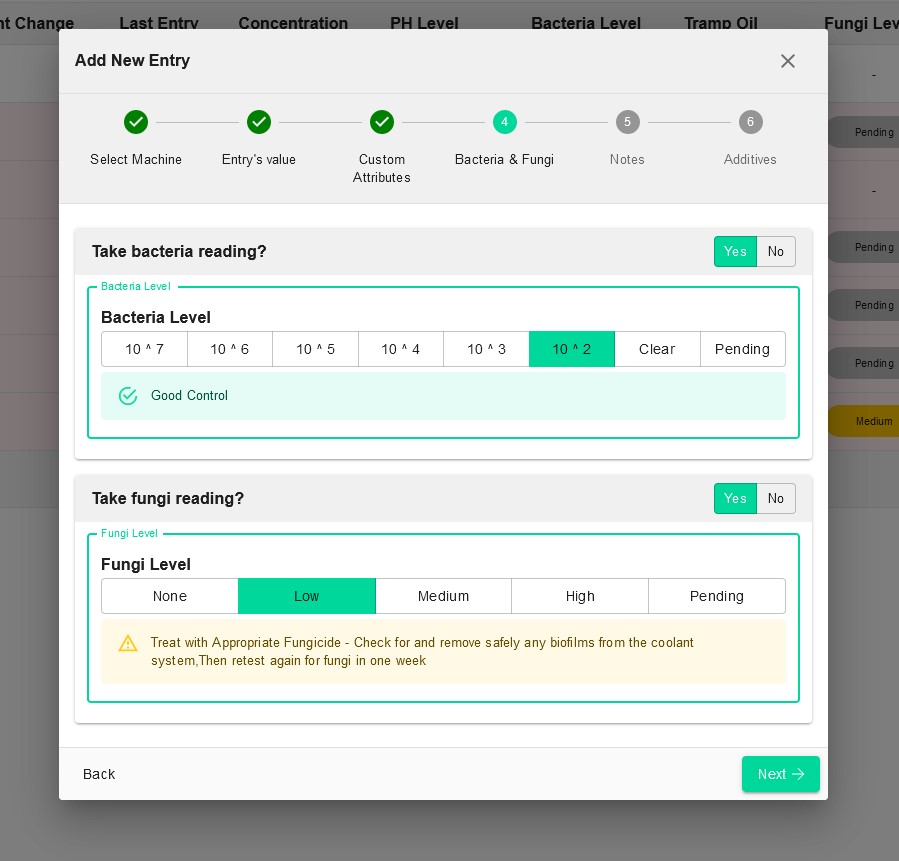

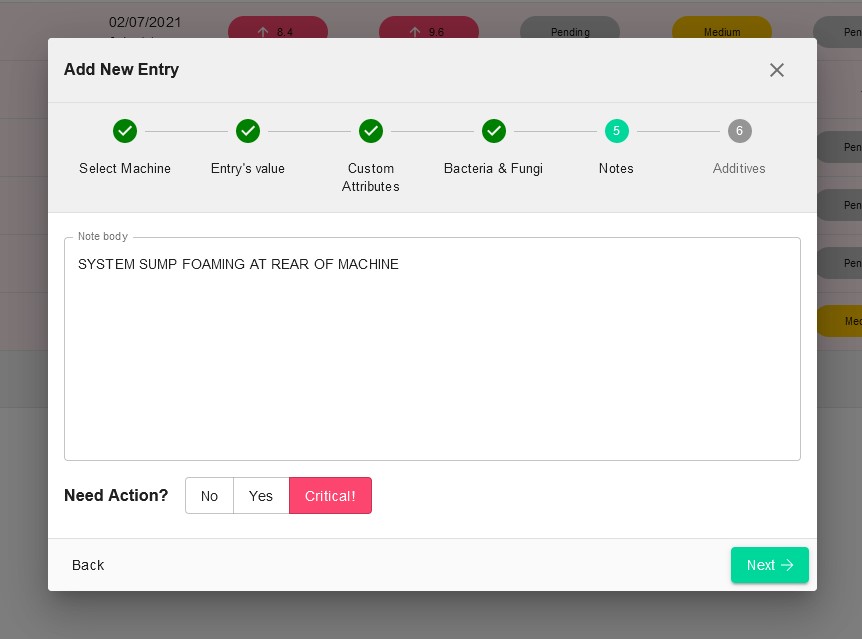

MWF Coolant Control

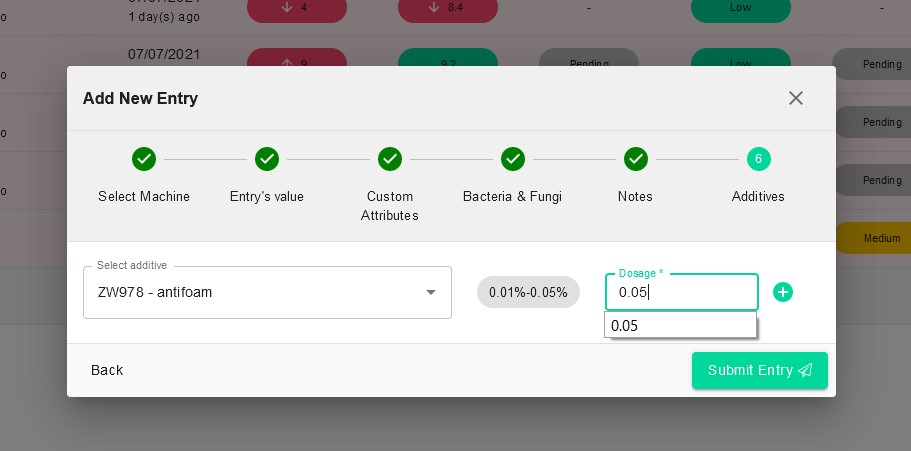

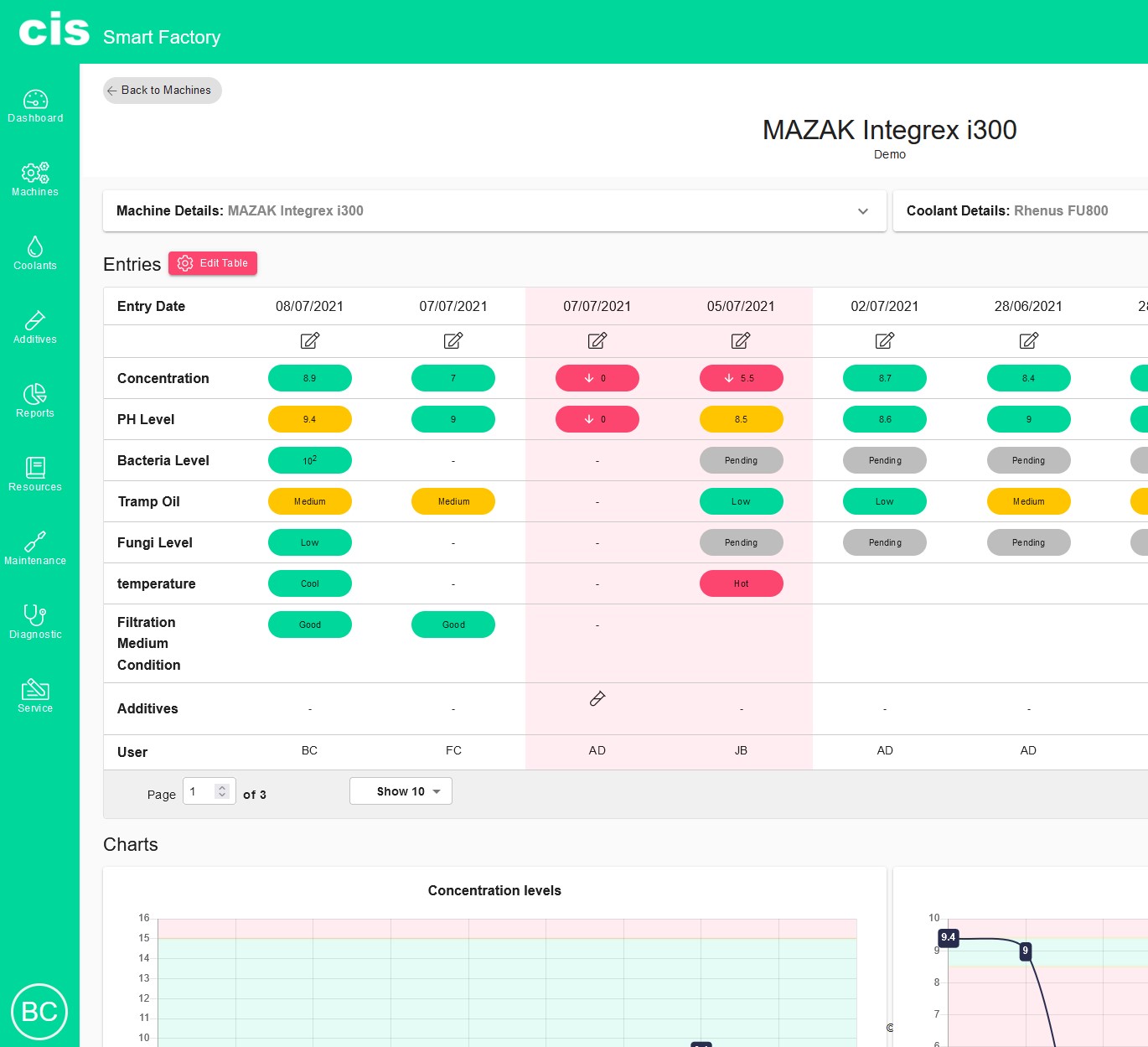

We have a number of hardware components and free comprehensive software monitoring and data record keeping control – of your Metal Working Fluids in your CNC machine shop.

Hand Tools

- Plier & Snips

- Files

- Hammers

- Deburring

- Riverting & Stapling

- Screwdrivers, Sanders, Impact Wrench

- Spanners

- Bolt Cutters, Chisels & Punches

- Torque Wrenches & Tools

- Hex Keys & Hex Bits

- Hacksaw Blades and Frames

- Screwdrivers

- Scrapers

Indexible Cutting Tools

- Grooving Tools & Inserts

- Indexable Drilling Tools & Inserts

- Indexable Inserts

- Indexable Milling Tools & Insert

- Sliding Head Tooling & Inserts

- Threading Tooling & Inserts

- Thread Milling Tooling & Inserts

- Turning Tools & Inserts

- Parting Off Tools & Inserts

Industrial Oils, Coolants & Lubricants

- Oil Absorbing Granules, Pads, Snakes, etc.

- Compressor Oils

- Anti-corrosives (dewatering fluids)

- Hydraulic Oils

- Cutting Fluids

- Anti-seize

- Greases Industrial Lubricants

- Penetrating Sprays

- Machine Coolants

- Sideway Oils

- System Cleaners

- Chain & Gear Lubricants

- Tapping Fluids & Compounds

- Mixing, Filtration, Cleaning, Transfer & Recycling

Precisions & Measurements

- Bore Gauges

- Calipers

- Depth Gauges

- Dial Gauges & Indicators

- Edge & Centre Locators

- Gauge Blocks

- Magnetic Bases Magnifiers

- Micrometers

- Pin Gauges

- Rules & Tapes

- Screw Ring & Plug Gauges

- Height Gauges, Tool Presetters

Raw Materials & Fasteners

- Bolts, Nuts & Washers

- Ground Flat Stock or Gauge Plate

- Industrial Marketing Products

- Keysteel

- Shim Stock

- Silver Solders

- Silver Steel & Tool Steel

- Socket Head Screws

- Stainless Steel Fastenings

Safety & Janitorial

- Eye Protection & Eye Wear

- Line Marketing Systems

- Hand Protection

- Clothing & PPE

- Head Protection

- Respiratory Products

- Skin Safety & Cleaning Products

- Janitorial Supplies; deb, Rocol

- Ear Protection

- Footwear & Overalls

Storage & Cabinets

- Benches & Cabinets

- Drawers & Cabinets

- Machinists Chest

- Maintenance & Tooling Trolleys

- Toolboxes & Toolbags

- Toolchests & Cabinets

Toolholding & Workholding

- Magnetic Chucks & Magnetic Products

- Drill Sleeves, Mores Taper & Accessories

- Clamps, Clamping Kits & Accessories

- Live, Dead & Face Driving centres

- Soft Jaws & Hard Jaws

- Vices & Accessories

- R8 Tooling

- Drill Chucks

Other Companies we work with:

- OPEN Mind

- MAPAL

- KOMET

- VERICUT

- Thames Stockholders

- EZSet

- KINTEK

- TaeguTec

- D’Andrea

- WALTER

- Dormer

- Vargus

- Mitutoyo

- Sandvik

- Renishaw

- Mitsubishi Materials

- Wohlhaupter

- Seco